Introducing ID Genève Unveils the Circular S Eclipse

Welcome to the hub of the horoloy

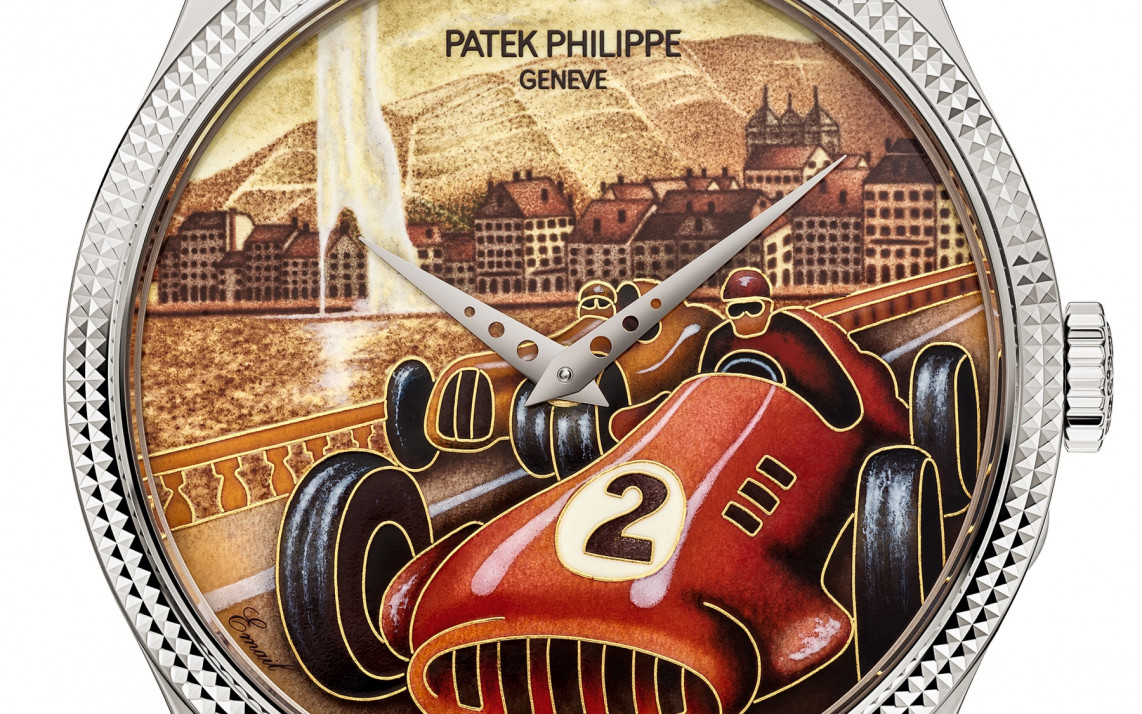

Is a type of artistic finishing that involves applying a glassy coating made from powdered glass mixed with special liquids.

In watchmaking, metal surfaces of the watch are coated with enamel, which is then exposed to high temperatures to ensure the stability of the coating on the coated surface. Enamel coating is used in coating watch dials, hour markers, hands, and other components.

Enamel is used to create dial designs that are resistant to fading and can maintain their vibrant colors for centuries. Enamel dials are often found in high-end and luxury watches because creating them involves a time-consuming and delicate process that requires a high degree of skill.

However, they are also delicate and can crack or chip if not handled carefully.

There are several types of enamel used in watchmaking, including cloisonné, champlevé, flinqué, and grand feu, each with their own unique characteristics and methods of application.

News Dubai Watch Week 2025 Will Be the Largest Ever with 90 Brands Participating

Editorial The Secrets of Watch Case Design

Hands on Phillips Presents Universal Genève’s First Timepiece Following Its Revival

Technical The Frequency, Why It Matters in Mechanical Watches

Introducing The New Chopard the L.U.C Grand Strike

Introducing Czapek Unveils the Time Jumper 10th Anniversary